Meeting in our manufactury in BISO Novaky

We will show you interesting pictures from the meeting in the factory

Our factory, BISO in Slovakia, Nováky and the long-awaited meeting on 27.11. 2022. Thanks to AgroVario Kft. from Hungary for coming despite the long journey and therefore we could show them our manufactury. Come with us to see how it went.

AgroVario Kft. in Hungary is a dealer of the Fendt brand, you can see them at the upcoming exhibition in Budapest at AGROMashExpo from 25.1.2023 to 28.1.2023, where the BISO VX Crop Ranger Trendline Light 650 header will also be presented.

Of course, we started the meeting with a coffee break before taking a look behind the scenes of the production.

Let's take a look at what we can see in the production plant.

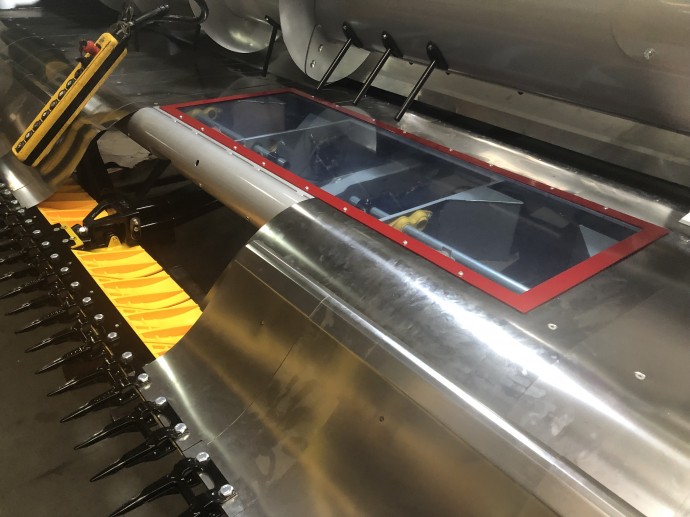

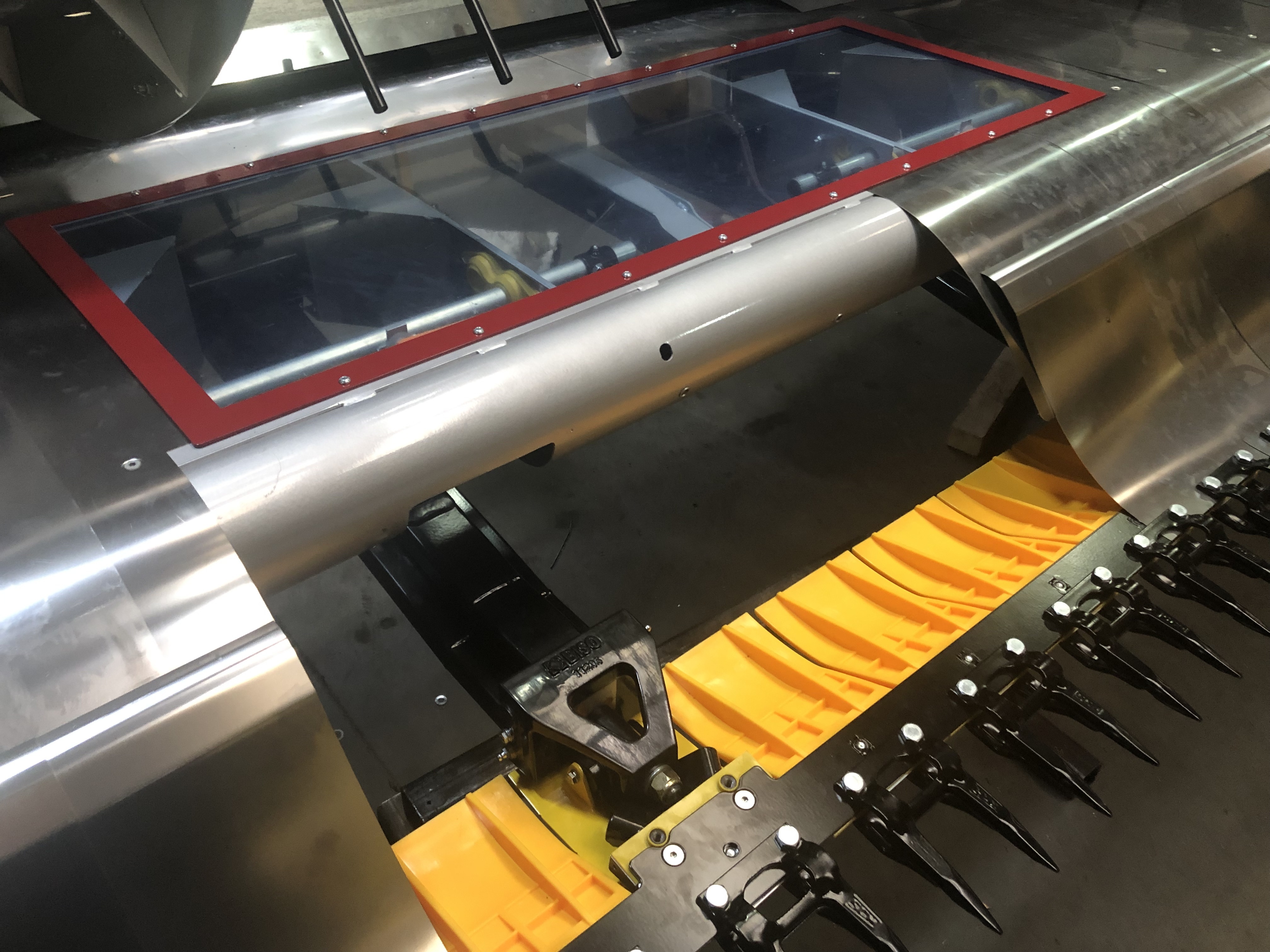

3D Varioflex AIR i headers are currently coming to life on the assembly line. It is a unique opportunity to look completely inside their operation and see in detail the elements that have been developed for several long years to the current, most successful state.

On the right, we see the hybrid frame of the third generation. The combination of aluminium and steel guarantees minimal bending effect and longer life of all bearings. Another advantage is the reduction of the header´s weight and increase in its strength.

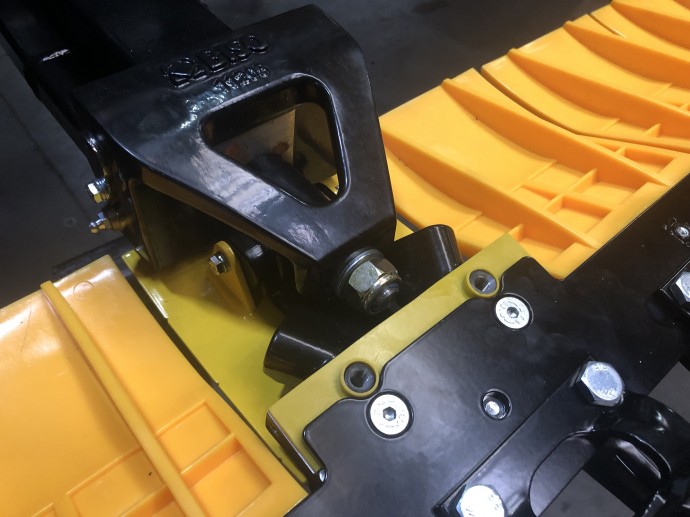

The robust, reliable and maintenance-free bottom extension solution of the BISO Vario system guarantees minimal losses on the cutting edge. All arms of the flex system move independently of each other. They are controlled by an intelligent system of sensing the pressure on the soil on the mowing scythe through air bellows and pneumatic valves. This is how active copying of the plot is achieved.

In the picture, you can see the flex arms – parallelogram controlled – float and are pivoted through air bellows.

Fully autonomous intelligent controlled flex cutter bar in one header with variable floor.

The ground pressure is measured at the cutter bar near the parallelograms by intelligent sensors. Thanks to this the mower blade is loaded only by bending, thus reducing the load on the drive and the wear associated with it.

See more pictures in the gallery.

Other interesting articles:

|

FIRST IMPRESSIONS OF THE BISO VX CROPRANGER VX850 TLL IN COMBINATION WITH THE NEW HOLLAND CX 8.80 COMBINE HARVESTER Now, all our combine harvesters are parked under the roof. And why not remember the sunny days of last summer, when we worked hard? What were our first impressions... |

|

|

BISO CROPRANGER VX TRENDLINELIGHT (PART 1) THE PULLING HORSE OF BISO COMPANY Its full name is BISO CropRanger VX TrendLineLight (TLL). The production has started in 2011 but don’t confuse it with CropRanger VX HighLine which was produced from 2001. CropRanger VX TLL is the latest ... |

|

|

BISO PROFISTEER TRAILER |