BISO - SOJAFLEX

A GOOD SOLUTION FOR SOYA HARVEST WITH A STANDARD HEADER

The SojaFLEX adapter from BISO was in offer in the first phase from 2005 for up to the 9m header width. This product is focused on all the brands with NO vario headers. In the flex mode, the load of the knife gearbox, the lever and the knife are so high that the actual width limit with a one side drive is 7.5m. BISO is able to produce the SojaFLEX extension for standard headers made by John Deere, New Holland, Case-IH, Laverda and Claas. We also have some unique solutions for the CLAAS VARIO headers up to the V750 model.

In the picture you can see the field after BIO soya harvest. On the left side it was done by Claas Lexion V750 header with the BISO SojaFLEX extension and on the right side by the competitor with a “mechanical” flex. BISO SojaFLEX is doing significantly well.

The goal is to cut the soya plant under the lowest “floor” of soya pods.

We have many different types of soya. In the picture you can see a very high stubble after soya harvest but, in this case, it was not a problem for the driver to lift the sojaflex module (header) a little because no pods were left on the ground.

The customers say that after harvest with a standard header they have “two floors” of pods left on the ground. And this means huge money. So the soya harvest is not an easy job. Every field is usually different and it is the same with the types of soya.

This is BIO soya with a really high weed. To harvest such a field is not ease at all. But with the increase of BIO soya producers this issue is starting to be actual.

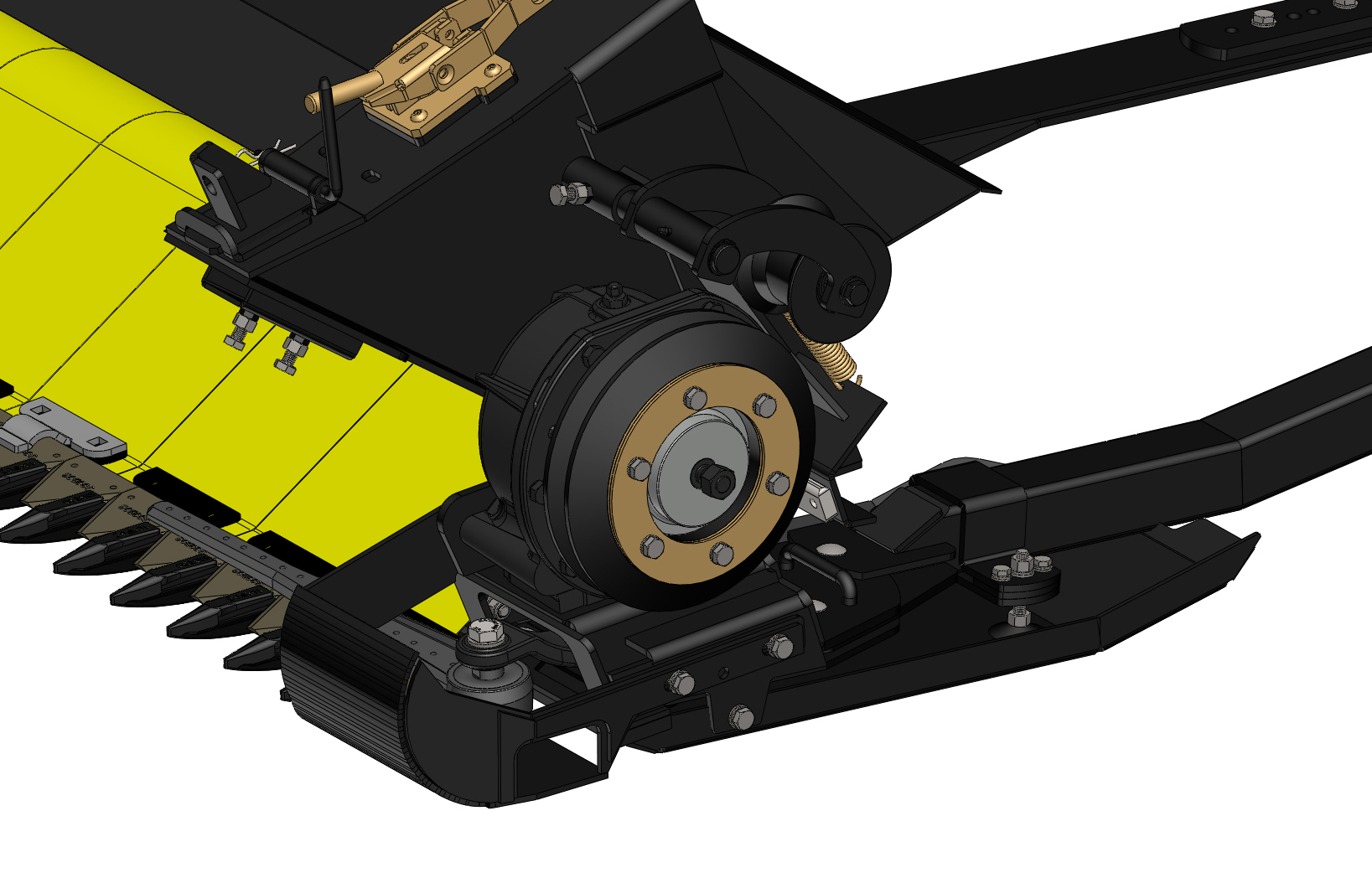

The BISO SojaFLEX extension kit contains the FLEX module in “mechanical” version with the drive. This means the knife gearbox with pulley, belt and tensioner. Plus a drive belt unique for every combine brand. The FLEX module is hooked on the standard header and fixed in position by long arms located under the header and bolted to the rear framer of the header. In this area small “ears” must be welded on the frame of the header. There is also the possibility to adjust the angle of the SojaFlex extension in this area. And this is very important for a correct work of the kit.

The SojaFlex extension from BISO can be fitted on all common standard headers on the market and on one vario header – Claas Vario. It is delivered by BISO as a KIT. For correct fitting, you have to calculate with two guys for one day minimum.

The FLEX module has its own skids and is flexible thanks to a row of segment spring plates. The SojaFlex extensions are equipped with BISO double fingers, a BISO knife, a knife head, a liver and a gearbox. As a new option in 2020, we will have a special conversion knife head and the extension should be ordered with Schumacher double fingers and knife. This is a wise choice for customers who work in rocky areas.

Long dividers

Both dividers are part of the kit from the factory - the left and the right one. The dividers are fully adjustable as is possible to see from pictures. For the 2020 season, the system of suspension has been changed to achieve a better and free movement upwards. Typical for soya are long dividers but some drivers have a little different strategy. Usually, it is related to the type of soya harvested in the region.

The left side is the key area with drive components. The kit includes the knife gear box with a console, the knife liver and the BISO knife head. From 2020, the company has the Schumacher kit in offer. This means a special knife head, a Schumacher knife and Schumacher double fingers.

The skids under the table. The FLEX module slides just on the row of such skids. The picture is made on the Laverda FreeFlow header.

The right side of the header. In this picture you can see very well the row of the SojaFLEX module skids, the connection to the Laverda FreeFlow header and the knife area with the typical soya flex long divider fully adjustable. The correct angle is the most important issue on the SojaFLEX modules.

The SojaFLEX module in action. In this picture you can see how the flex module copies the ground. In this case, the double finger angle is not aggressive. In the front area we can see the gearbox lever protection shoes.

The maximum width is 7.5m

The load of the driveline, if the header is working in the FLEX mode, is really high. All depends not only on the field conditions, but also on the wear of the knife and double fingers. Thanks to this and the experience from the field, we offer the extension of 7.5m as the maximum width for all brands (7.6m respectively). The technology gives the owner the possibility to cut soya really low in the ground area as the fingers touch the ground with very good effectiveness of the harvest.

The Claas Lexion 760 combine with the V750 vario header with BISO SojaFLEX extension. Slovakia, 2019. The vario header from Claas is only one type of vario header where it is possible to fit the BISO SojaFLEX module.

In this picture you can see how easily can the driver adjust the cutting height on the basis of local conditions. In this case, it was easy to harvest soya which was cultivated mechanically by row crop cultivators without tracks from the sprayers.

And again, the Claas Vario V750 with the BISO SojaFLEX module. In the picture you can see that the drive works with the reel to feed the crop in the auger area fluently. The Claas combines have no header angle adjustment so the basic fitting must be done in a correct way during the mounting of the extension. The combine has no automatic function of the reel. The driver must adjust the reel limiter is such a way, that he will not touch the knife area of the flex module with the reel steel spring fingers.

Look at the right divider on this Lexion combine with the BISO SojaFLEX module. The driver is using only a simple spring steel loop with the right end of the knife free. In some types of soya, it can be a good solution because green materials have no space for packing and blocking the crop flow.

This is starting to be a typical picture in Slovakia. The BIO soya treated very well by row crop cultivators with a specific profile of the ground. On such a field, you can make very good results already with the mechanical SojaFLEX module. On standard fields, the biggest issue during soya harvest we have is with the sprayer tracks.

More about the SojaFLEX extension KIT: http://navigator.biso.eu/en/en-biso/harvesting-technics/biso-soja-flex-2/

Leaflet version in ENG for download: http://navigator.biso.eu/wp-content/uploads/2015/02/Product_range_BISO.pdf

Other interesting articles: