BISO – SOJAFLEX FOR CLAAS VARIO

CLAAS VARIO HEADER FOR SOYA HARVEST WITH BISO SOJAFLEX KIT

We have updated the SojaFLEX extension for CLAAS Vario headers significantly in 2019. In the pictures below you can see the biggest available model, the SojaFLEX 7.5m for V750 vario header. With such a kit you can harvest soya on a professional level with the standard V750 vario header from CLAAS. SojaFLEX extension from BISO is a “mechanical” SojaFLEX module with a flexible cutting bar.

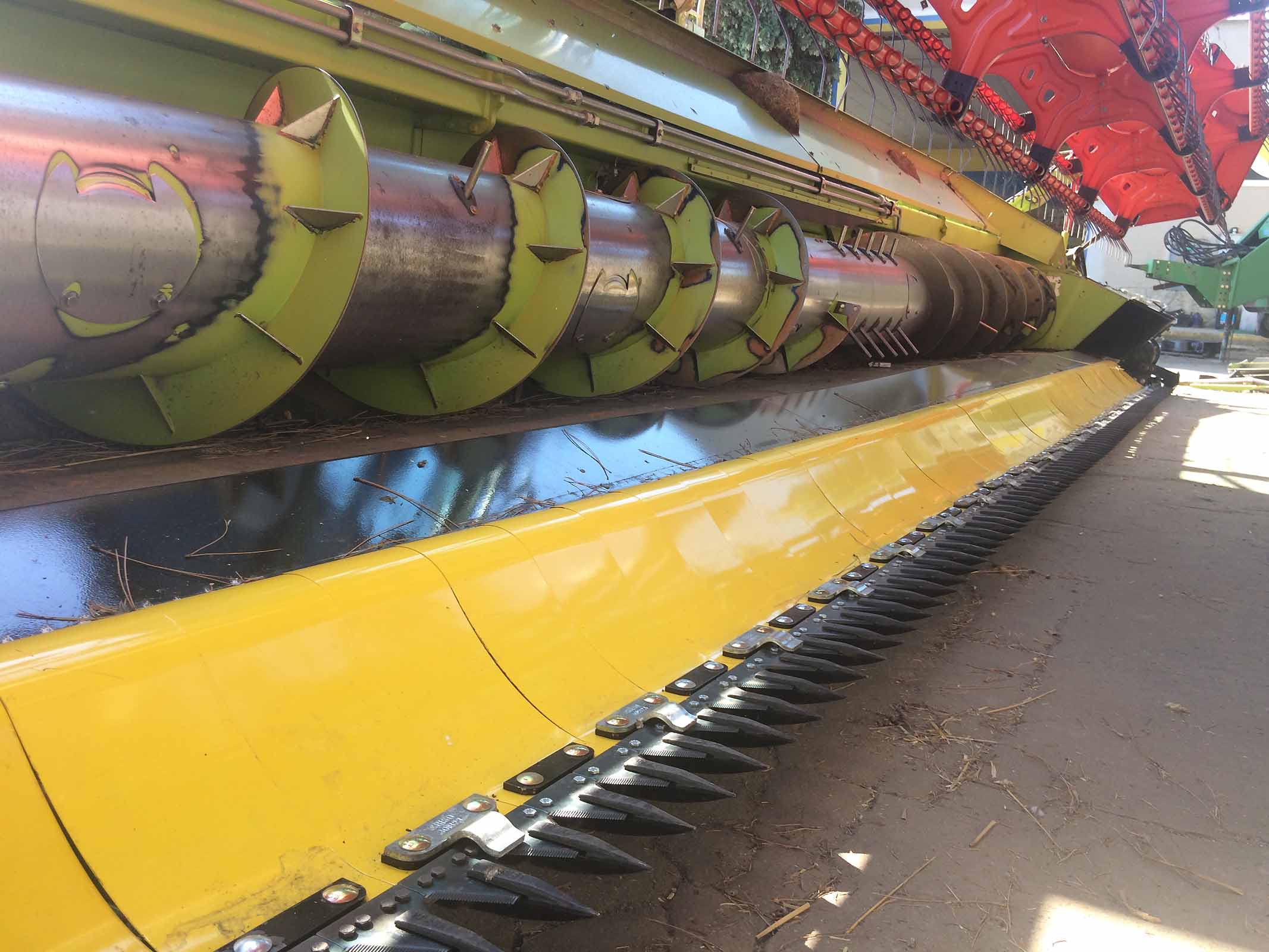

The BISO 7.5m SojaFLEX extension fitted on the CLAAS VARIO V750 header. The long dividers are fully adjustable.

The CLAAS combines don´t have angle adjustments, so the position of the header against the combine is fixed. In the picture you can see what is the position of the header above the ground and what is the position of the BISO SojaFLEX module.

The SojaFLEX module is a mechanical flex module with many skids. The driver is able to adjust the angle of the skids on the rear hitches. Details of this system will be shown later.

Claas Lexion 760 in action. Part of the BISO KIT is the flex module with a left-hand side drive with many own skids, a BISO gearbox, a knife liver, a BISO knife and double fingers, and two long dividers.

In the picture you can see the long divider, model 2019. Suspended, fully adjustable. The long left bar is missing in the picture and the driver has removed the protection skids of the knife head – a very aggressive approach in weeded areas.

The BISO serial plate on the main frame, the left-hand side near the gearbox.

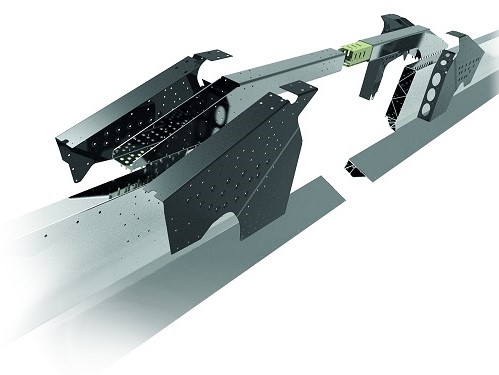

The new BISO SojaFLEX 7.5m KIT ready for fitting on the combine.

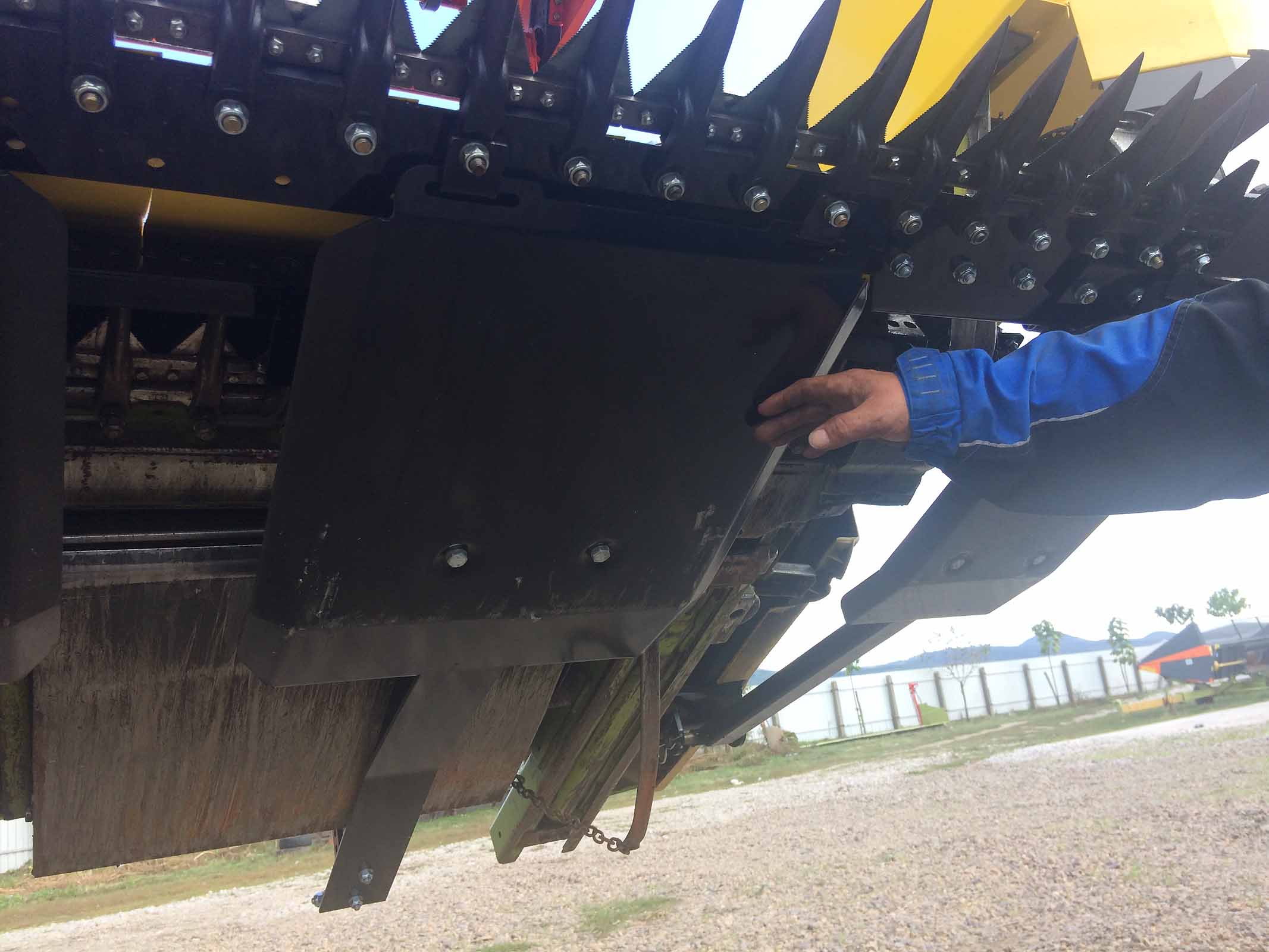

The BISO SojaFLEX extension kit contains the FLEX module in “mechanical” version with the drive. This means the knife gearbox with a pulley, a belt and a tensioner. Plus a drive belt unique for every combine brand. The FLEX module is hooked on the standard header and fixed in position by long arms located under the header and bolted to the rear framer of the header. In this area small “ears” must be welded on the frame of the header. There is also the possibility to adjust the angle of the SojaFlex extension in this area. And this is very important for a correct work of the kit.

The FLEX module has its own skids and is flexible thanks to a row of segment spring plates. The SojaFlex extensions are equipped with BISO double fingers, a BISO knife, a knife head, a lever and a gearbox. As a new option in 2020, we will have a special conversion knife head and the extension should be ordered with Schumacher double fingers and knife. This is a wise choice for customers who work in rocky areas.

Long dividers

Both dividers are part of the kit from the factory - the left and the right one. The dividers are fully adjustable as is possible to see from pictures. For the 2020 season, the system of suspension has been changed to achieve a better and free movement upwards. Typical for soya are long dividers but some drivers have a little different strategy. Usually, it is related to the type of soya harvested in the region.

Left sidewall of the CLAAS Vario header. The first models of BISO SojaFLEX requested to cut some material in this area, but from 2019 we have changed the design with minimum request for cutting the header frame.

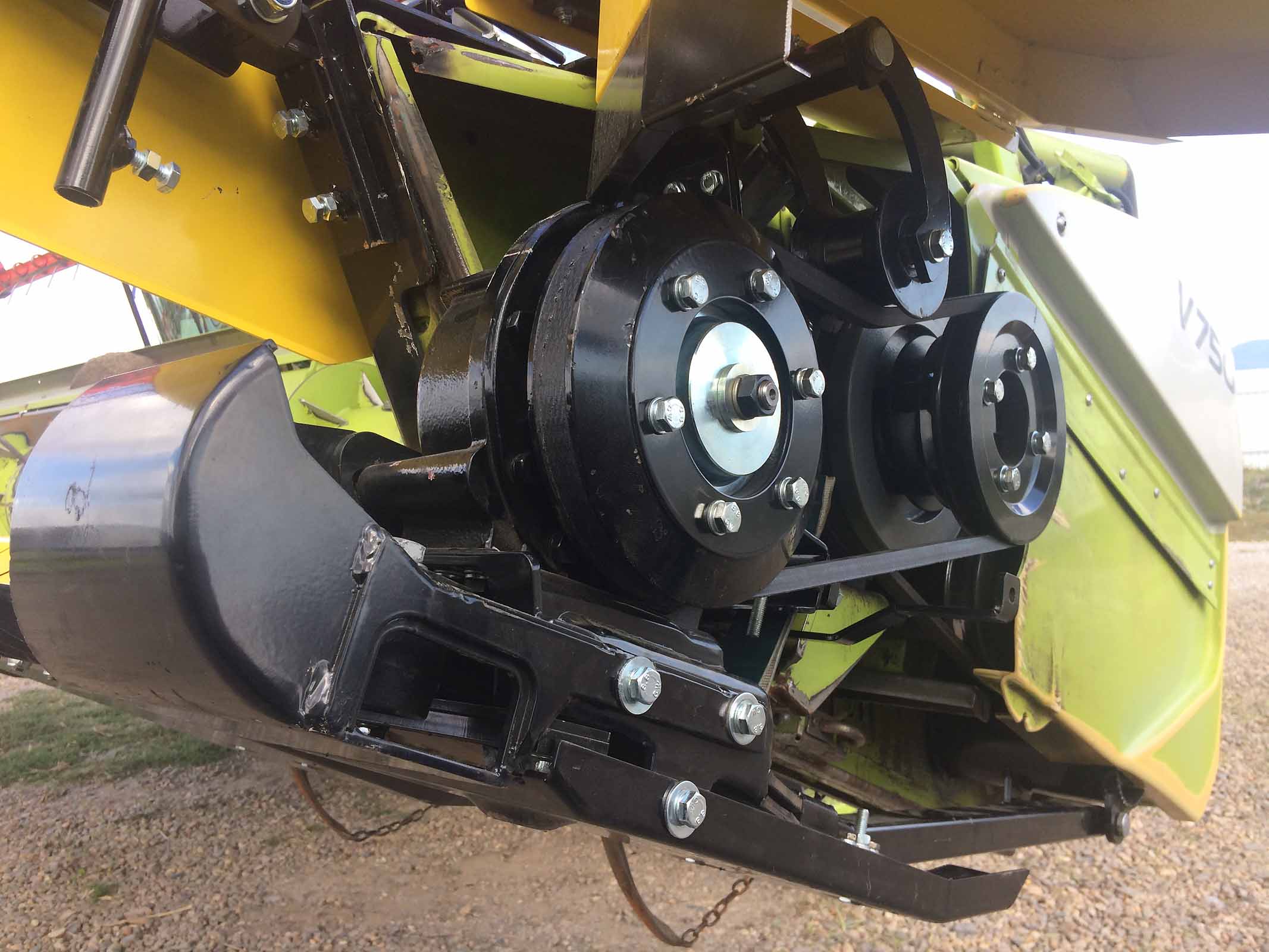

The original belt pulley on the CLAAS knife gearbox and the BISO pulley from the kit.

The combine drivers will lift the SojaFLEX module as well as the rapeseed adapter did a few years ago.

The knife gearbox has its own skid with a stronger arm.

A shot from the right side. The knife bar angle (double fingers angle) is very important for the correct work.

Last two double fingers on the right side are protected with a small skid fit eye for belt hitch. The strap is limiting the maximum movement of the knife bar. Nearly the same is on the left side.

The SojaFLEX module already fitted on the combine header. In the picture you can see the position against the header auger.

The yellow plates are from spring steel. On this unit, we have standard BISO double fingers and the standard BISO knife with rough blade elements. The same that we use on the BISO headers.

The gearbox position on the left frame.

The knife bar of SojaFLEX module. The original CLAAS knife bar is hidden behind the module. The best way is to take out the knife or only disengage the drive (knife head bolt).

In this picture you can see the position of the BISO SojaFLEX knife and the original CLAAS knife.

The long skids of the SojaFLEX module with long arms under the header frame.

The design of the skid in the knife head area (the left side).

And the rear hitch. The small eyes must be welded on the frame in some cases. We can adjust the angle of the FLEX module skids here.

One of the two quick couplers on the right side of the frame.

A detail of the rear hitch and the position of the arm under the header floor.

A look from the right side. The long bar of the divider is removed in this picture.

In this picture you can see where the FLEX module knife bar is if the header is put on the ground.

A NEVER ENDING STORY – WHAT IS THE BEST double finger height and angle ….. and shape. Don’t forget that when you go down you make a perfect job, but it will cost you some money for the wear of the knife and double fingers.

Not precise measurements, only for your imagination. In a standard soil in the field, the double fingers “touch” the ground.

In this picture you can see the upper quick coupler, the position of the long divider and the gearbox cover (just opened).

The skid under the knife gearbox. The front part is protecting the knife head and lever with a bolt and it is possible to remove it. If you work on a soft and wet soil with no rocks, you can do it and decrease the weight of this part. The cleaning effect will be excellent after this.

In this picture you can see the position of the BISO SojaFLEX module against the CLAAS combine header including the pulleys with the belt. Thanks to the weight, this module has a stronger arm than the others.

In 2019, we have changed the design of this pulley.

The same pulley fitted on the original one.

The rear hitch in detail.

And another one.

For the SojaFLEX, we use the standard BISO knife gearbox with six bolts from underneath.

The position of the belt tensioner has been changed a little bit for the 2020 season.

Compared to conventional headers (the protection of the knife head and the knife liver is much more robust and working as a part of the skid itself. For the 2020 season, we have updated the shape of the skid so that the front part will be different (longer).

Pictured here is the spring of the belt tensioner and behind it is the strap as a maximum lift limiter.

And the complete kit on the header. In 2020, the belt tensioner pulley position, the long divider suspension system mechanism and the shape of the protecting shoe will be different.

To demonstrate the FLEX module, everybody uses extreme situations. But this picture is showing the “normal working day” of the flex module with the working width up to 7.5m.

And again, the knife bar with BISO fingers and the BISO knife. In 2020, we will fit the SojaFLEX extensions with the Schumacher kit as was already mentioned.

A situation when the header was lifted up a little.

… and the position of the header in this situation.

The setup with BISO double fingers. Working very well, only sensitive to stones.

On BISO SojaFLEX, you can use the standard double fingers thanks to the use of many skids (on every arm). So the load is transferred on the ground through these skids and not through the wide shape of fingers or the special shape of the knife bar. Our solution is very simple and universal from the service point of view.

And this is the reason why BISO SojaFLEX does such a good job in the field. It is better than the original headers with the flex knife bar because the flex module is not a part of the header and is designed especially for soya harvest.

The header on the Claas Lexion is fully lift up and we can see the position of the skids on the header and very important is to notice the position of the double fingers.

Here we can see the position of the rear hitches with the adjustment mechanism.

Detail – what is behind the skids.

A skid arm in detail.

The right limiter – a strap and a special small skid.

And the move up.

The left arm behind the gearbox – a detail on the rear hitch with a grease nipple.

The left skid in the bottom position – the strap is active.

The same situation.

And a look from the front.

A view behind the spring plates above the skids.

And the position of skids when the header is lifted up.

The position of the gearbox when the header is lifted up.

CLAAS Lexion 670 with vario header V750 with SojaFLEX extension from BISO.

The flex module in action.

And once again.

In this picture you can see very well how soft is the flex modul on BISO SojaFLEX.

And the result in the field.

The field after harvest with our BISO SojaFLEX extension should look like this.

More about the SojaFLEX extension KIT: http://navigator.biso.eu/en/en-biso/harvesting-technics/biso-soja-flex-2/

Leaflet version in ENG for download: http://navigator.biso.eu/wp-content/uploads/2015/02/Product_range_BISO.pdf

Other interesting articles: