BISO PROFISTEER TRAILER

A HYDRAULIC FOUR WHEEL STEERING SYSTEM

It is a very pleasant feature for the 9m header, it is good to have it on the 10.7m one, and for the 12.3m one it is a “MUST HAVE”. We are speaking about the rear axle steering on the header trailer. Let’s look at the BISO ProfiSteer trailer for big headers and comfortable drive. How does it work?

Not every field is perfect. Sometimes it’s difficult to drive on the parcel and fit the header on the combine. It’s not possible to see it in the picture, but the header hang up was made in a serious slope.

This is a typical situation. As contractors, the drivers have no easy life. We have a 10.7m header on the ProfiSteer trailer.

You can see in this picture that you have no chance with a standard tandem axle. It will be very difficult with the ProfiTrailer (less rear axle steering). It’s true that the combine will pull the trailer much more to the left side thanks to the opposite system of the steering.

The left front wheel is in the air – not touching the ground thanks to a slope in two directions. It is a big advantage of the ProfiTrailer with a central front dual axle which is not sensitive to such situation. It is clear, that a central beam will touch the ground. There are no lines under the beam with a risk of damage.

In the area of the feeder house, there are no wheels (the same as on the ProfiTrailer). The combine connection is very comfortable. The advantage of ProfiSteer trailer is stability on 4 wheels base.

Such a trailer is not cheap. This is clear at first sight. But there is one thing that rises the combine´s value by a hundred-thousand Euro – the header.

Not all combine crews are of two drivers. It’s becoming a new norm that a combine is driven only by one person. And in this case, a good trailer is more than important. Easy to use, perfect to drive.

You can see 4 supports on this trailer. It is normally better to use 6 supports for the 10.7m header. But in case of the new 3D VarioFlex Air I with a completely different design of the sidewalls, we don´t use the supports under the sidewalls as on the standard vario headers.

The number and the position of the supports is very important for every header brand´s lifetime. We believe that the header frame does not die in the field, but on the trailer during the transport.

BISO ProfiSteer header trailer – HOW IT WORKS

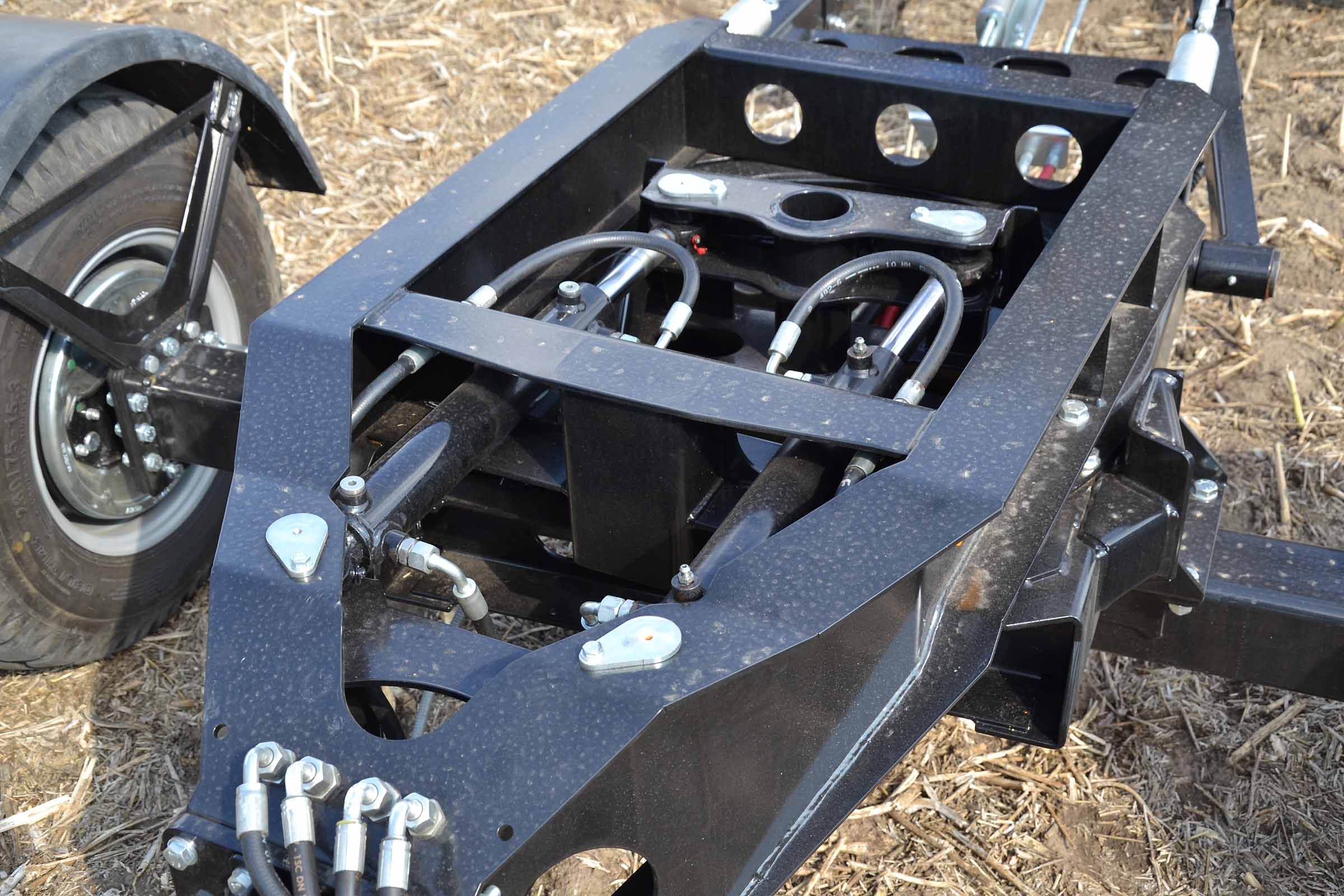

Let’s start in a simple way. We have two hydraulic rams on the steering bogie of the front axle. If we turn the drawbar to the left or right side, the hydraulic rams pump the oil into the rams on the rear axle. The wheel hubs of the rear axle with vertical pins are the same as on the tractor´s front axle with connecting rod between the rear left and right wheel. There is no mechanical connection between the front and rear axle.

Thanks to this solution we have more driving strategies just like with mechanical steering. You can hydraulically lock the steering of the rear axle and use the ProfiSteer as a standard trailer all the time.

We have a little bit different header supports on this trailer.

Hydraulic steering

In the standard steering mode, the rear axle follows the track of the front trailer axle. It is important to adjust the steering of the rear axle to the centre for a straight drive. For this purpose, we have the manual hydraulic pump and some valves in the box on the trailer on the right side in front of the rear axle. You can close the valves and pump the rear wheels manually in central position.

This pump gives us another advantage. If you are stuck somewhere on a farm yard in the corner and you know, that the header will not pass through, you can go to the black box, put the valves in correct positon and you can manually adjust the rear wheels as you need. It takes some time but in a really critical situation this function can help a lot. And this is the main advantage of the hydraulic steering.

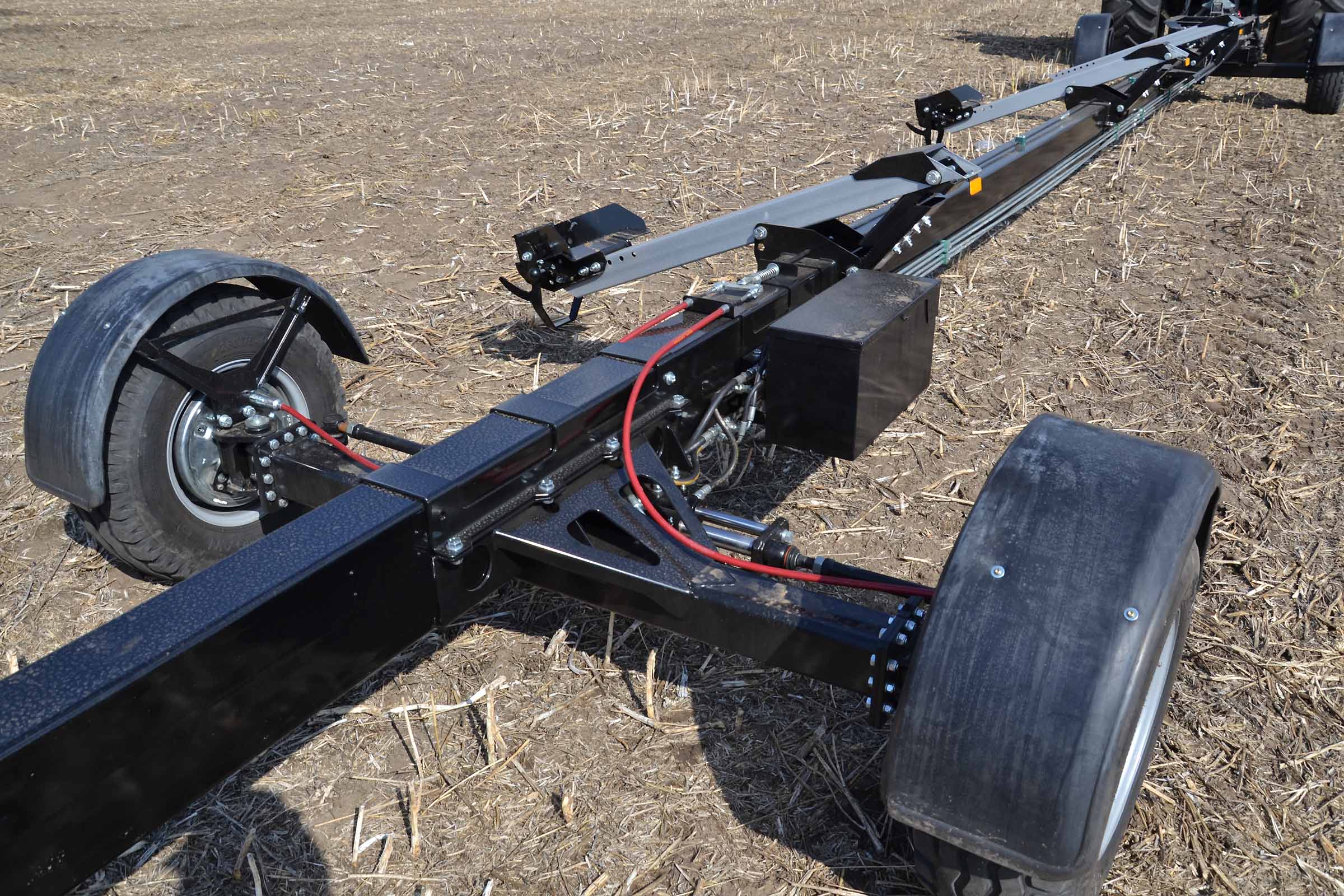

Brakes

In the picture we have a 40kph version with brakes on all four wheels. The system is called “overrun brake system”. There is an ALKO towing eye integrated in the towing drawbar with the overrun brake system actuator. There is a drum brake in every wheel. Brake lines between the wheels and the drawbar are mechanical with a rod and lever system and red Bowden cables.

This is the BISO ProfiSteer header trailer. This is a unit for 3D 10.7 headers only with 4 supports. It is possible to order a 40kph version as pictured here.

The steering bogie of the front axle. In the picture you can see very well the two hydraulic rams of the rear axle steering.

The design of the front axle has a lower profile than the one on the ProfiTrailer. The profiles are opened with good access to the hydraulic rams and hydraulic lines.

In the front wheels, the drum brakes are mechanically controlled the same way as on the rear axle. The mudguards are not missing.

There are two red arrows on the steering bogie. They indicate the central position of the drawbar.

The hydraulic rams on the rear axle are integrated in the connecting rod of the rear axle.

And the red indicators in detail.

The drawbar is a standard one. The ALKO kit for the overrun brake system. The same is used on the ProfiTrailer. The small red cable is for security. Not fitted on the tractor in the picture.

Rear drum brakes in detail. The brakes adjustment is very important. It’s good to check the brakes temperature during long transports time by time.

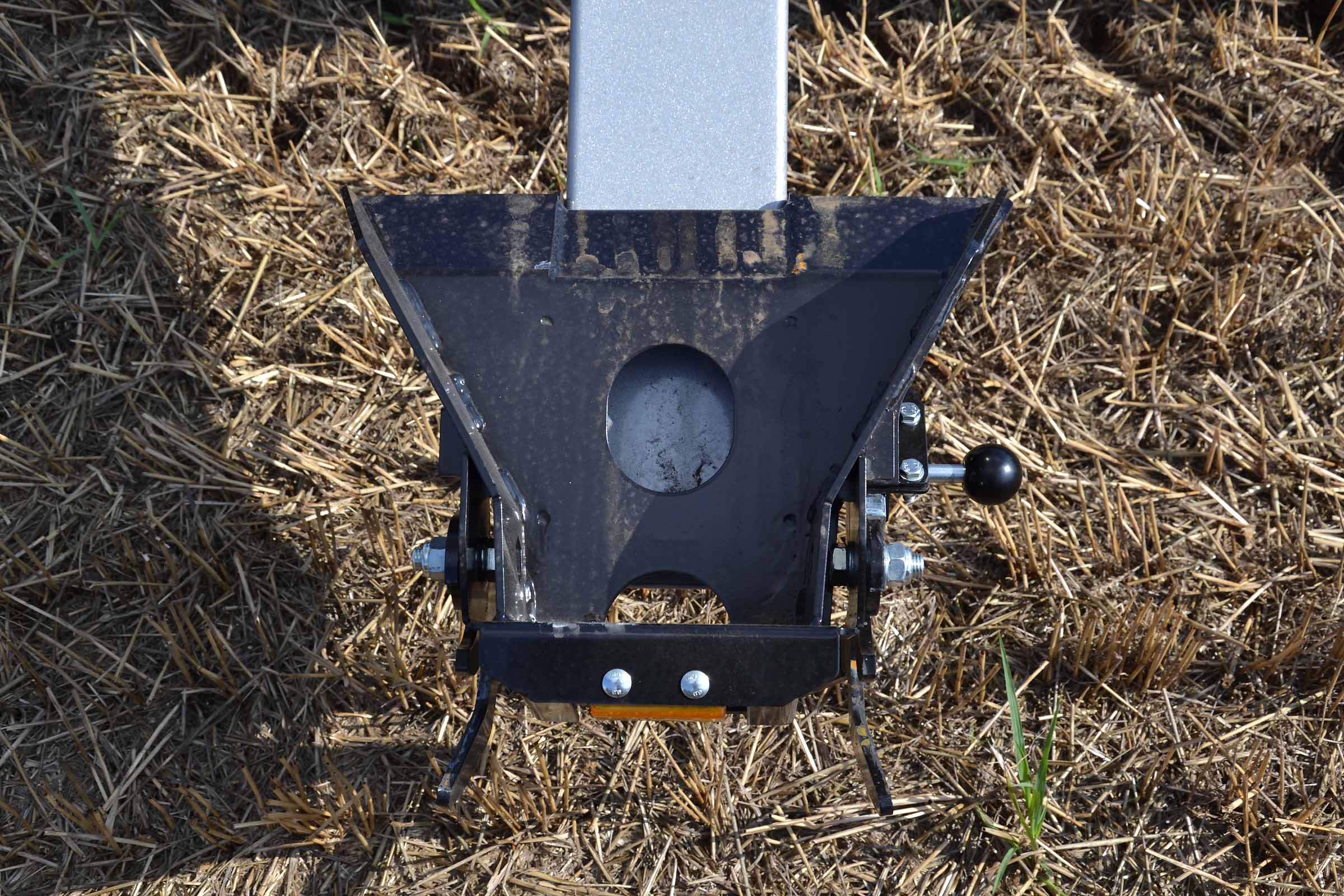

Fully adjustable BISO supports. The main beam profile depends on the header length.

The red cables are the brakes control mechanical lines. The mechanical systems are easy but for the correct adjustment, the fix position of the rear axle is important. In case of overloading the trailer, it is possible that the rear axle will move a little on the main beam. In such a case, it will change the brakes adjustment.

The hydraulic lines are on the side of the main beam of the trailer frame. Not below it. The brake lines are on top of the beam. In this picture, you can see the “black box” with all hydraulic control valves and a hydraulic hand pump for manual steering of the rear axle.

The rear wheel hub with a vertical pin is bolted to the rear axle beam. The hydraulic rams and connecting rod are located in front of the rear axle.

The control “Black box” with hydraulic valves and a hand pump (on the right side).

The new locking system of the header on the internal supports.

And a second picture of the same component. The new version is guiding the header better in the correct position during the disconnection of the header from the combine.

Two chocks have the holder in the rear part. It is a very important safety feature.

The rear light bars are locked by two screws. This component often suffers some damage during the transport. Thanks to safety rules this part can’t be foldable (you can see a good example of such a typical damage in the pictures on the left side light bar).

The spare knife holder – a standard solution as on ProfiTrailer.

Easy to use, perfect to drive

For understanding better how the ProfiSteer works, it is good to take a tractor and drive it with a trailer in your farm yard to make short tests on different roads. You can see very well from the tractor cab what the steering system really does. In this case, you will get a better feeling before you connect the trailer with the header behind your combine. It’s not a bad idea to make some “short training” in the manual mode and try to manage the rear wheels with the manual hydraulic pump. In some critical situations such a good knowledge of the whole system will be a big advantage. The same is about the adjustment of the central position of rear wheels before the first drive or after manual adjustment.

The ProfiSteer has no steering vertical pins on the front axle thanks to the use of a bogie front axle. An advantage of this hydraulic system is, that if the wheels are pushed by a load peak, the hydraulic steering system will “dump” the load peak a little and after that it will move the wheels in correct position. Because of this you can sometimes feel some delay.

For better understanding what the ProfiSteer trailer does behind the combine, it´s good to take a tractor and drive it on familiar fields. Then look back at what the trailer is doing. From middle class tractors, you will have a perfect overview on the trailer.

In comparison with ProfiTrailer, the ProfiSteer uses a lot of the same components, but the trailer is different. Generally, the front and rear axle.

In a moment when the tractor is going in the curve with the trailer and the front bogie axle with a drawbar is starting to turn, the hydraulic oil is pumped up to the rear axle steering hydraulic rams.

You can see, that the front axle follows the tractor in a standard way.

In a moment when the tractor is changing the direction, the oil is pumped in the opposed direction.

The tractor is going in a left turn.

And the rear axle is following the front axle.

And that’s it.

The header will follow the combine. For the 12.3m headers it is a “must”.

It’s possible to see in this picture, that the rear axle is following the front axle with some delay.

And again, the left corner.

… and the reaction of the rear axle steering system.

On the combine, the movement of the rear hitch is much more progressive than on the tractor.

In such a situation, the trailer follows the track of the combine. It´s very comfortable and safe for the driver.

The stability of this trailer is very good. There are no lines under the central beam.

The drawbar has a towing eye with an overrun brake system just like the standard CropRanger. The steering hydraulic rams are integrated in the front bogie axle.

And the same in the right corner.

The front axle is turning the rear wheels hydraulically.

And here we can see again …

… how perfectly is the rear axle …

… following the front axle of the ProfiSteer trailer.

It works very well on a flat yard, in a town or at a roundabout.

It’s a method, how to transport big headers in a very comfortable way. You don’t need it for the 8.5m. For the 9m headers, it´s a big plus point and a driving comfort feature.

And for the 12.3m headers, it is the only way to survive.

The rear axle in detail. The hydraulic rams are in front of the rear axle.

The hydraulic system has one important advantage. You have no mechanical connection between the front and rear axle.

In this picture, you can see the manual hydraulic pump behind the rear axle (it´s a 5-6 year old trailer, when the pump was not yet in the hydraulic block).

With this pump, you can make a manoeuvre like this without any movement with the drawbar. You can drive the rear axle manually where you need, if you are blocked somewhere.

In such critical situations, you have a variability of driving of the rear axle.

And again, a good example of how does the steering logic work and how does the rear axle follow the front axle.

The technical level of the header trailer should be in line with the technical level of the header (pictured with BISO ULTRALIGHT 1230).

Such a manoeuvre is impossible with a standard trailer.

We have two variants in production and pricelist: the 25kph and the 40kph.

And again, the header in the corner. As it was mentioned, the front axle is in front of the header and the frame has a very low profile.

It is clear, that thanks to the hydraulic system it is not a problem to adjust the position of the rear axle as you need. After changing the header model for a smaller working width.

This trailer has 4 supports. For the 12m headers, it is good to have 6 supports.

At night, every small detail is important. The safety is in the first place. And, good to note, every mistake costs important money.

The same during long transports. Contractors know such stressful situations. And it’s really funny, if you know, that your trailer is still behind you like a clever well-disciplined dog.

Conclusion

The ProfiSteer is a modern header trailer for big headers from BISO. The trailer uses hydraulic steering between front and rear axle with the possibility to switch from AUTO mode to MANUAL mode. You can choose from the 25kph or the 40kph version. All wheels have drum brakes with mechanical control. The ProfiSteer significantly increases the driving comfort of a combine with a header and of the safety at the same time.

More about the BISO ProfiSteer trailer: http://navigator.biso.eu/en/en-biso/harvesting-technics/biso-profi-steer-2/

Leaflet version in ENG for download: http://navigator.biso.eu/wp-content/uploads/2020/04/Headertrailers_NH_eng.pdf

Other interesting articles: