OUR STORY

COMPANY BISO DEVELOPED IN 1954 FIRST STRAW CHOPPER FOR CLAAS COMBINE. BUT THE REAL STORY NOT STARTED WITH THIS …

The BISO ERNTETECHNIK, BISO SCHRATTENECKER and BISO developed a wide range of successful and technologically interesting products during last 50 years. Everything is turning around new 3D VARIOFLEX - new header category, but the interesting story of company producing harvesting technics for combines started in 1985 with rapeseed extension later called BISO INTEGRAL CX100. But let's start from actual time.

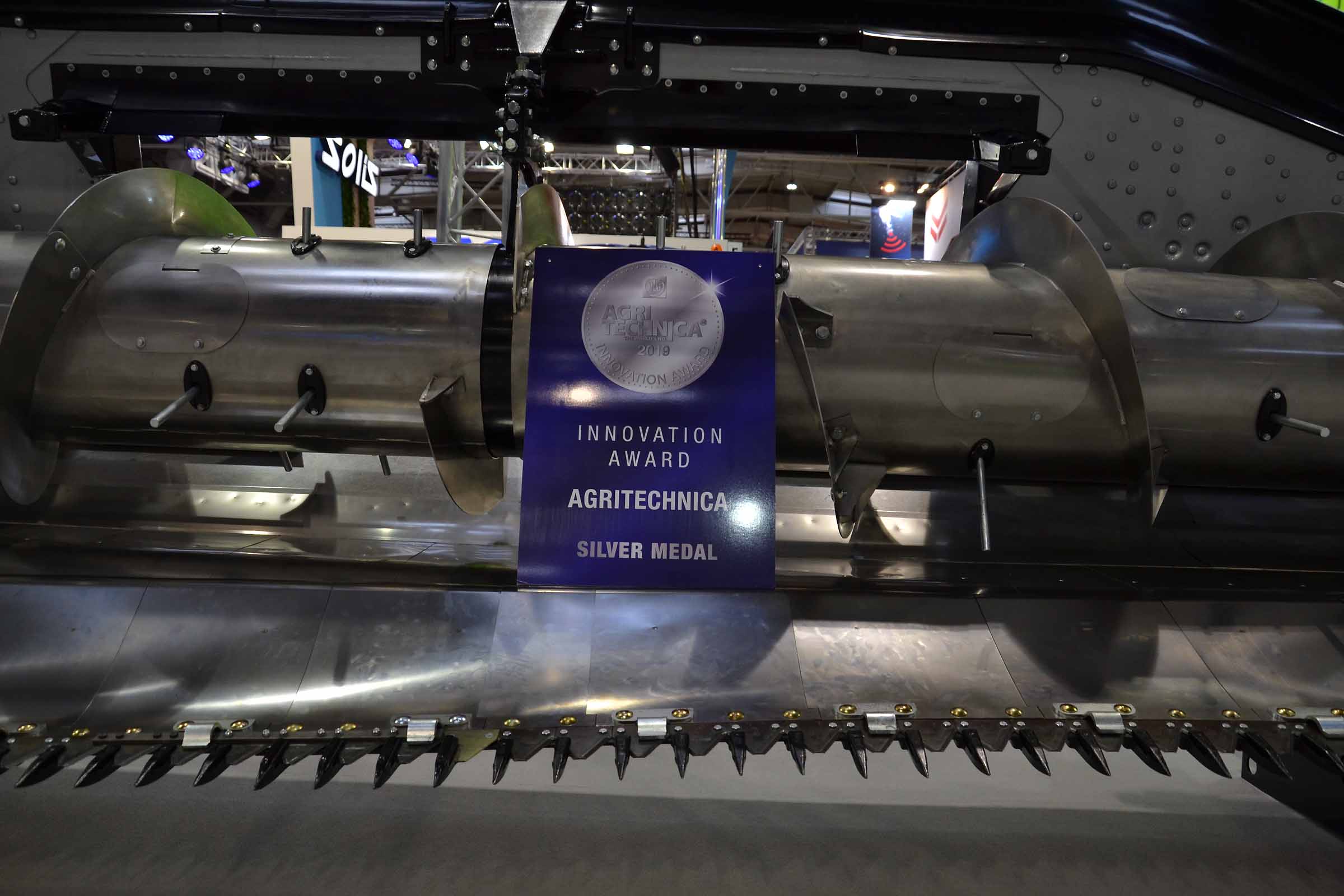

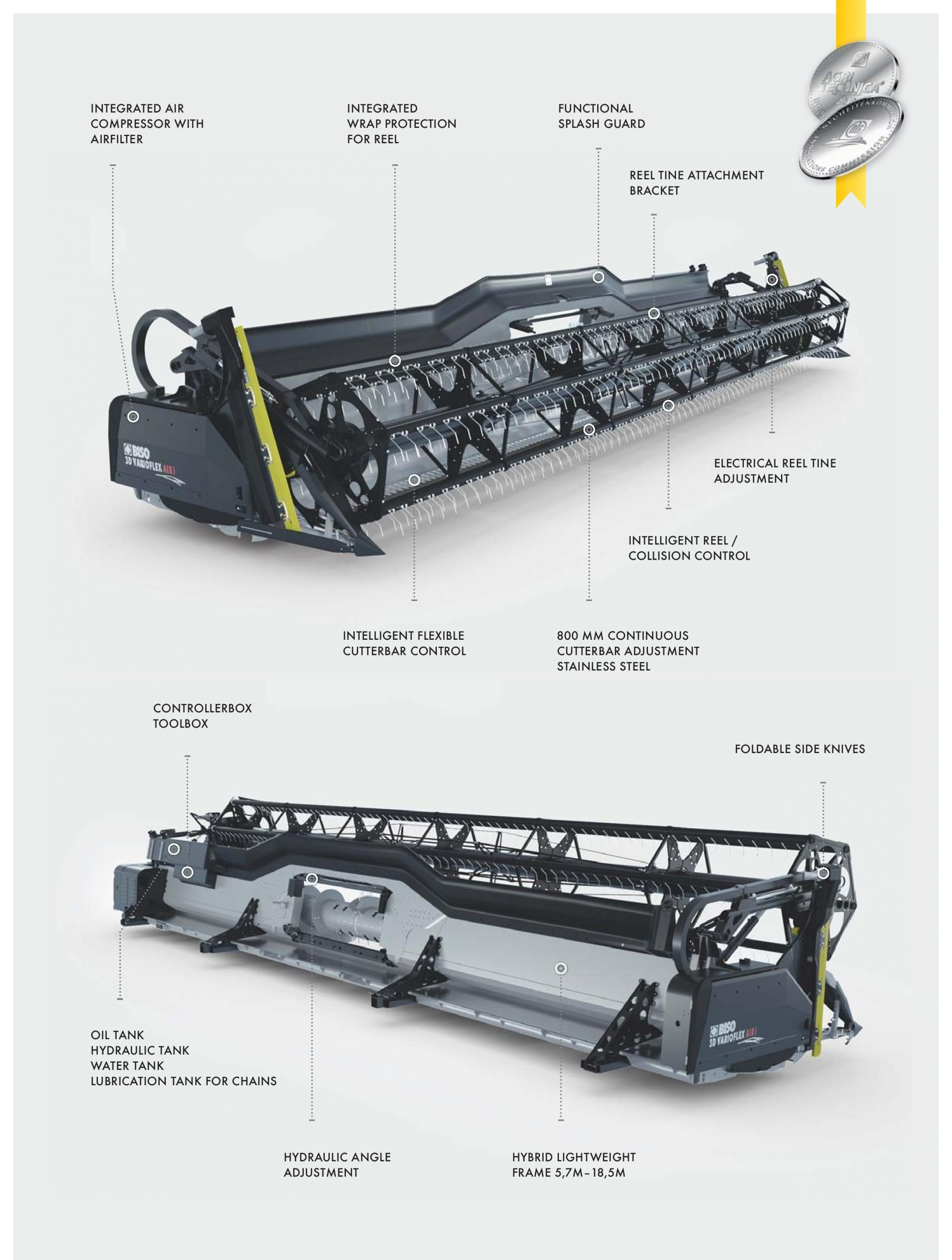

The great success from 2019 – the BISO 3D VarioFlex AIR I got a silver medal on Agritechnica Hanover fair.

2019 – BISO 3D VARIOFLEX AIR I – silver medal on Agritechnica

BISO is coming on the market with completely new header which setup new 3D class category. New header is integrating vario system with flex module, air suspension and completely new intelligent system of ground pressure adjustment from 2-50kg. All this technology is integrated in well approved HYBRID frame. In November 2019 on Agritechnica it was first time when we showed the new header to our customers and the first reaction of them was more the positive.

The BISO 3D VarioFlex AIR I is completely new header with hybrid frame, FLEX module with parallelogram, air suspension and with many intelligent functions. And of course all this in combination with vario table. The 3D is NEW CLASS.

2017 – BISO 3D VARIOFLEX AIR i

We started the testing program with first real 3D in 2017 on our company combines. The 3D VARIOFLEX AIR i is a header with FLEX module with parallelogram. The knife is never loading with torque and the system have air suspension with special sensors for adjusting the "intelligent" functions like adjustment the ground pressure from 2-50kg. The header have many automatic functions. The driver can activate the FLEX module and work completely in automatic mode. With this header you can harvest all crops including flat crops, soya and peas in top quality up to 14m working with. This header is able to feed very well the biggest combines on the market. The BISO is expecting, the new 3D category will be standard in near future like vario system 20 years ago.

Demonstration of 3D header class technology – how gently is cutter bar touching the ground with integrated fully automatic intelligent function of FLEX module with independent parallelogram's ...

... and this is the result in wet and VERY sticky soil. You can adjust the ground pressure from 2 up to 50kg ...

... this is AIR i ...

... for all conditions.

We where running many tests in very specific conditions – different crops and different soils. 3D is completely new world in header technology but above all this Hitech features the our header is more then smart to drive – very easy to handle.

Tests from 2017 in different soya fields. Some of them were "not easy", but for software calibration it was very important period of new header development.

AUTO mode for long day with stable and perfect performance up to late night. BISO intelligent functions of AIR i are all the time "FRESH".

In some periods during last 15 years the turnover of BISO GROUP was 40% in production and 60% in trading.

In 2014 was BISO GROUP active in many countries with direct BISO braches in Austria, Czech, Slovakia, Romania and Bulgaria. On the picture is the HQ in BISO Romania.

2013 – BISO ProfiSteer header trailer

With an ULTRALIGHT headers BISO introduced on the market new ProfiSteer trailers with hydraulic automatic steering of rear axle. This trailer is something like standard equipment for headers 10.7m and more.

BISO ProfiSteer with BISO ULTRALIGHT 1230 header. The advantage of hydraulic steering is, that in the yard you can manually steer with hand pump rear axle in some critical corners.

You can see, that rear axle is perfectly following the front axle "like a small dog".

Combine is different like a tractor. Combine is moving left and right with his rear part much more aggressively like a tractor. It is nice to test the driving system with tractor – you can see perfectly what the trailer is doing. With ProfiSteer is the transport with 12m header very comfortable and with 9m header you "don't know about him".

2013 – BISO ULTRALIGHT with HYBRID frame (3rd generation)

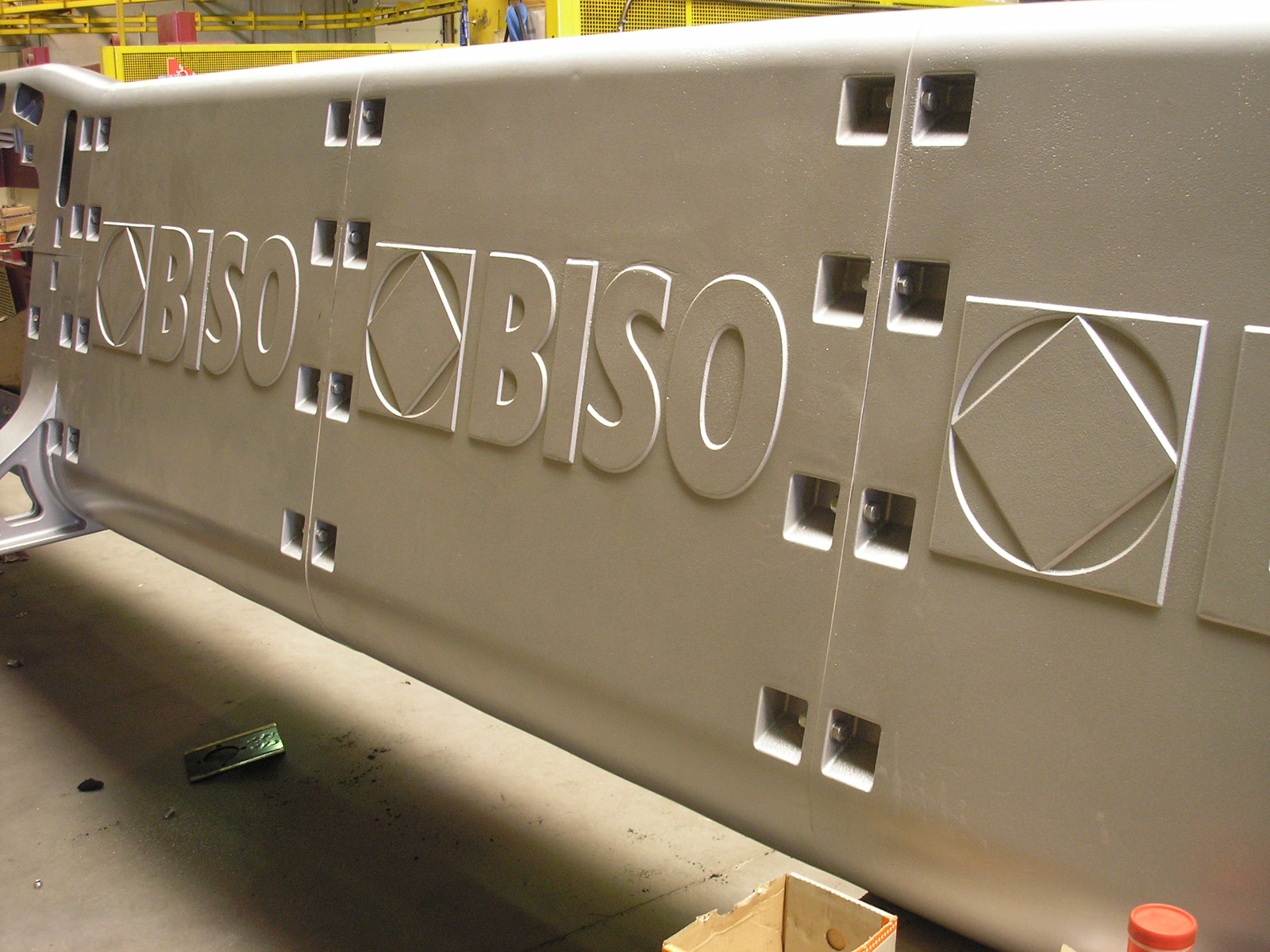

HYBRID is coming in production in end of 2012. Introduced on Agritechnica 2013 in Hanover. Its 3rd generation with frame from aluminum sandwich profiles in combination with steel frame parts (for example the central console for connection to combine feeder house). And on the base of combination aluminum and steel parts the frame got very fast the new name HYBRID. Many people are calling this model line as "new ULTRALIGHT".

In offer were 3 models 1070, 1220 a 1410 in 2013. Most of produced headers have aluminum sidewalls (the drive is usually from both sides) as result of extreme pressure on weight saving. The main market for this type of header was Germany. The models of Ultralight 2nd and 3th generation are working in UK, Australia or Canada. Important market from this point of view is also Czech and Slovakia. The customers which are driving this headers 5 and more years are appreciating the frame strengthens and high lifetime off all moving parts. Very strong frame had already ULTRALIGHT 2nd generation, but thanks to hybrid frame the 3rd generation got against competition extremely strong backbone with very high lifetime of all bearings and moving parts with minimum stress of auger less risk of cracking.

Slovakia summer 2015 – the CR9.80 SmartTrax with ULTRALIGHT UL1230 with ProfiSteer trailer.

The ULTRALIGHT UL1070 with John Deere STS 9880i in Czech Republic (2013). This is the 3th generation with hybrid frame.

The harvest of rapeseed is very comfortable with ULTRALIGHT headers. You can very easily switch from wheat or barley to rape seed. On most of ULTRALIGHTS you can stand up the side knives by hydraulic system of the header from the cab ... maximum comfort.

The BISO varioheaders are giving to driver the choice. The vario in front position is most of the drivers not using only in rapeseed, like you can see on the picture. Many drivers are moving with vario table during harvest of every crop in relation to actual crop, weather and field conditions.

2011 – BISO COMPACTOR

The BISO COMPACTOR is a standard machine with many varieties of "working sections" for seed bed preparations. In offer was the foldable models 4m, 5m and 6m. The units are sold generally in Romania, Czech and Slovakia.

BISO COMPACTOR 6000 working in Czech Republic. On the picture is the unit with single rear cambridge roller, but the most popular is with double roller.

2011 – BISO CropRanger VX TrendLineLight (TLL)

The BISO CropRanger VX750 TrendLineLight (TLL) is the "pulling horse" of BISO company for many years. Very reliable, easy to maintenance with very good frame and lighter like competition. Many of them have plastic floor (ROBALON) and less angel adjustment with electric side knives. Very popular by contractors thanks good ration between price and specification. Usually delivered with BISO ProfiTrailer.

The CropRanger VX TrendLineLight (TLL) have different system of vario in comparison with CropRanger HighLine. The vario table is moving with sidewalls (including dividers) and if you will switch off the header drive, you can use all header hydraulic functions.

After many years the "best spec" requested by professional customers is usually hardox floor with angel adjustment. Officially it is possible to order angel adjustment only with hydraulic side knives. The angel adjustment is available as kit for retrofitting on the headers with electric side knives.

The BISO CropRanger VX750 TrendLineLight (TLL) is the "pulling horse" of BISO company. On the picture with New Holland CX8070SL during harvest 2013 in Czech Republic. With electric side knives, plastic floor, less angel adjustment, with lifters and ProfiTrailer.

For the fields less rocks you can less any problem use plastic floor. The electric side knives from BISO have very good reliability and in the service are in some regions very popular. The circuit breaker is on the combine near accumulators. It's very easy to restart the system.

The CropRanger VX750 TLL in "standard" BISO spec is a perfect header for high performance combines like CX8070SL. The CX8080SL is able to match with VX850 with very good results. The ProfiTrailer is a good solution for both headers.

After many years we have from customer's very good response about steel frame life time less any crackage and troubles after 10.000ha. Above 7.5m it is better to choose hybrid frame.

From 2016 the BISO is supplying the Deutz-Fahr factory with CropRanger TrendLineLight as OEM deliveries in DF colors. The headers for DF have hydraulic side knives and are usually fitted with Schumacher knives and double fingers. The DF combines have angel adjustment as part of feeder house.

It is not FLEX but many customers is using CropRanger VX TLL for soya harvest with very good result. All depends on field conditions. With this header you can touch the ground with double fingers less any problem.

Sampo COMIA C6 with „BISO KIT" – the BISO CropRanger VX450TLL with special BISO SwiftTrailer (or TandemTrailer). For bigger COMIA C8 and C12 is CropRanger VX TLL perfect solution.

Smaller BISO CropRanger VX650TLL on small 5 straw walker combine CX5090SL works perfect. Such a header is often delivered with BISO TandemTrailer.

2010 – BISO ATLANT trailers

The BISO ATLANT trailers company offered in Czech in Slovakia on the base of contract with Czech supplier Novasteel. BISO more times attacked the "trailer segment" and usually with very good products. This segment is heavily price competitive market and the trailers where sold usually by BISO branches in Czech, Slovakia and Romania.

BISO ATLANT 20 – standard trailer for very popular trailer segment.

This model line BISO ATLANT was at this time very modern and with possibility to order many interesting options. The trailers are working up today and they are very robust.

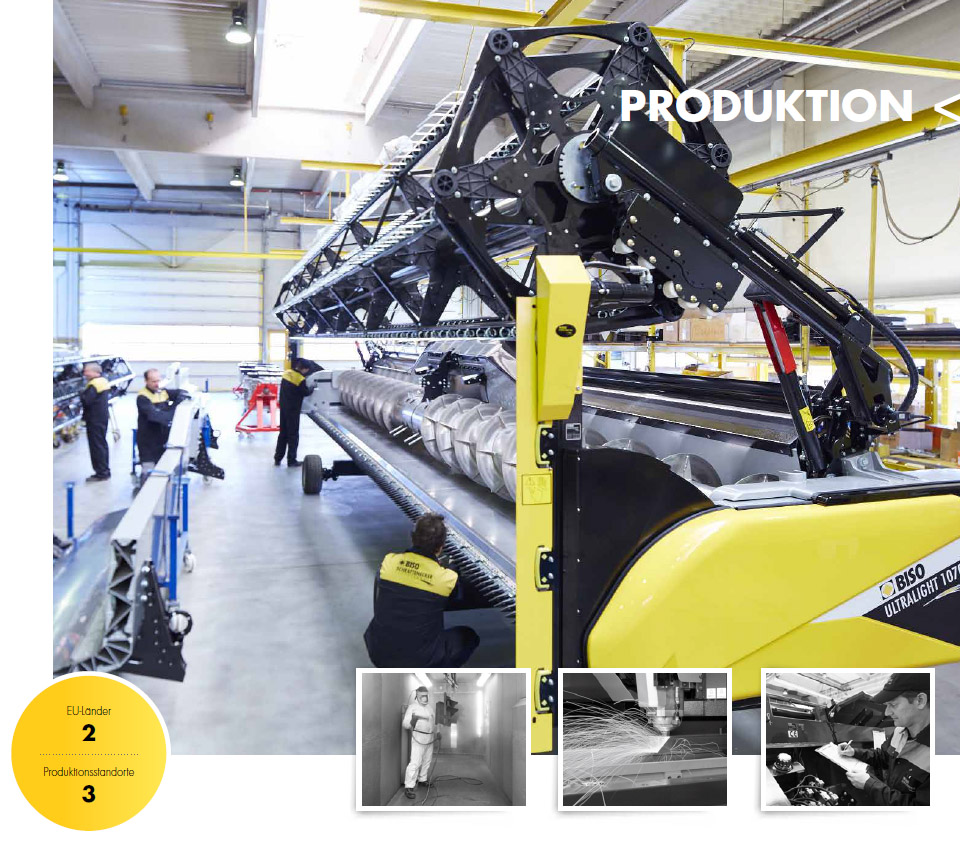

In 2013 the main production facility is factory BISO Ort im Innkreis (Austria). In second factory – BISO Novaky (Slovakia) is runningg the production of CropRanger VX TLL model line.

2008 – BISO ULTRALIGHT with aluminum frame (sectional one)

This was the first generation of new header with new name – ULTRALIGHT. The frame was from aluminium and was built from the sections for easier repairs. The sections where glued together and screwed. The model line name was BISO ULTRALIGHT 800 (vario movement 80cm) and with this header BISO started to work in real life with 12m headers in field.

The BISO ULTRALIGHT 1200 with CR9090SL "BlackLady" during the tests (2010, Czech Republic).

With ULTRALIGHT 1200 was BISO learning what means "12m world". Customer with 12-15m soil cultivation machines have zero problem with 12m header (Blazovice, Czech Republic)

In this time we realized what is real capacity of flagships on the market. Our CR9090SL Elevation had incredible performance and his key limit was the header. Such combines need enough "material" for good performance. With 12m header you can hit 100ha per day less any problem.

The header looks very good. Including details. Against the competition it was big step forward.

The vario system on ULTRALIGHT headers was impressive. The performance of the header was very good.

Typical view on "sectional frame". The modules were glued together and screwed. The idea, that from the service point of view it will be possible to change the damaged module was in reality not requested.

First BISO ULTRALIGHT 870 sold in Czech Republic in 2008. In service up till now. On the counter this header have about 8.000ha.

It's about right technology in right time. The combines heavily increased the performance during last 20 years and needs better and bigger headers. In some regions was 9m header standard 10 years ago and actually the owners of big combines are asking for 10.7m or 12m header.

2008 – BISO CropProtector sprayers

In 2008 we introduced on the market the new product in BISO colors – the trailed sprayer on the base for cooperation with Czech company MGM. This sprayers were offered on the Czech and Slovak markets.

The BISO CropProtector sprayer. Most of units had tracmatic system, 4000 liters and 24 meter steel arms with Mueller electronics.

The BISO CropProtector during demonstration in East Slovakia in 2008.

2007 – BISO CORNPOWER maize adapter

The offer is all the time the same: 5, 6, 8, 12 rows. Only fix frames. BISO is using own gearboxes with standard set up of vertical axle of dual chopping knives. Produces for row distance 70 (Romania) and standard 75cm. As option can be ordered and angel adjustment (hydraulic) if the combina have on feeder house no front face manual adjustment system (combines not setup for maize).

The most popular model is BISO CORNPOWER 8-75 (8row). With CX8080SL in Slovakia 2008.

The same model in 2013 in Czech Republic near BISO Tisnov branch with CX8080SL. After many years we can say that we have very simple, reliable product with low running costs and in Czech and Slovakia with direct service and technical factory service support.

The BISO CORNPOWER 12-75 on Tuln fair 2007 (Austria).

In 2010 was tested in Slovakia the 8row CornPower with foldable frame. This specification was never introduced in production

In 2013 is research and development located in Austria factory in Ort im Innkreis. Last ten years the company is heavily working not only on headers and combine adapters, but many other machines is in-house developed like disc harrows or compactors.

2007 – BISO X80/X90 tractors

On the base of cooperation with Chine YTO tractor producer we started big project. In the first phase we focused on models BISO X80 and BISO X90, later BISO X90N, BISO X100 and X125. This models are simple mechanical tractors based on FIAT AGRI technology.

Tractor BISO X90N with new cab from YTO. Czech Republic 2011. The unit have 4 cylinder engine with turbo, synchro gearbox with mechanical revers, A/C, air suspended seat, 40kph.

Typical specification of BISO X90 and front loader from STOLL. Many of this tractors have more then 20.000 hours now.

Our stand with BISO YTO tractors on Techagro 2010 in Brno. Rear is the BISO X80 with forest structure from Manatech company

The key models delivered by BISO were X80 and X90. Besides this company delivered some units od X100/X125 with common rail engines from Perkins and small X50.

2007 – BISO FixFramer and SemiFramer ploughs

In this year we introduced on the Czech and Slovak market under BISO name the range of mounted (FixFramer) and semi mounted (SemiFramer) ploughs on the base of agreement with Czech plough producer company SUKOV. All this models had only fix frame (no vario) and securing by bolt.

Mounted plough BISO FixFramer BS-5 (Slovakia 2007).

All the models of BISO FixFramer ploughs had fix frame. Memory valve was as option.

The name of the whole model line was BISO FRAMER.

This is semi-mounted BISO SemiFramer BS-6 in very hard conditions of South Slovakia (2008).

2007 – BISO CropTrailer

This new range of two and three axle trailers was the first attempt of BISO with such a product under own colors. For this reason we cooperated with Czech company ZDT. The trailers were delivered only on Romania market .

The first BISO trailers CropTrailer line make us good name in Romania.

2006 – BISO CropRanger VX1200 PremiumPlus

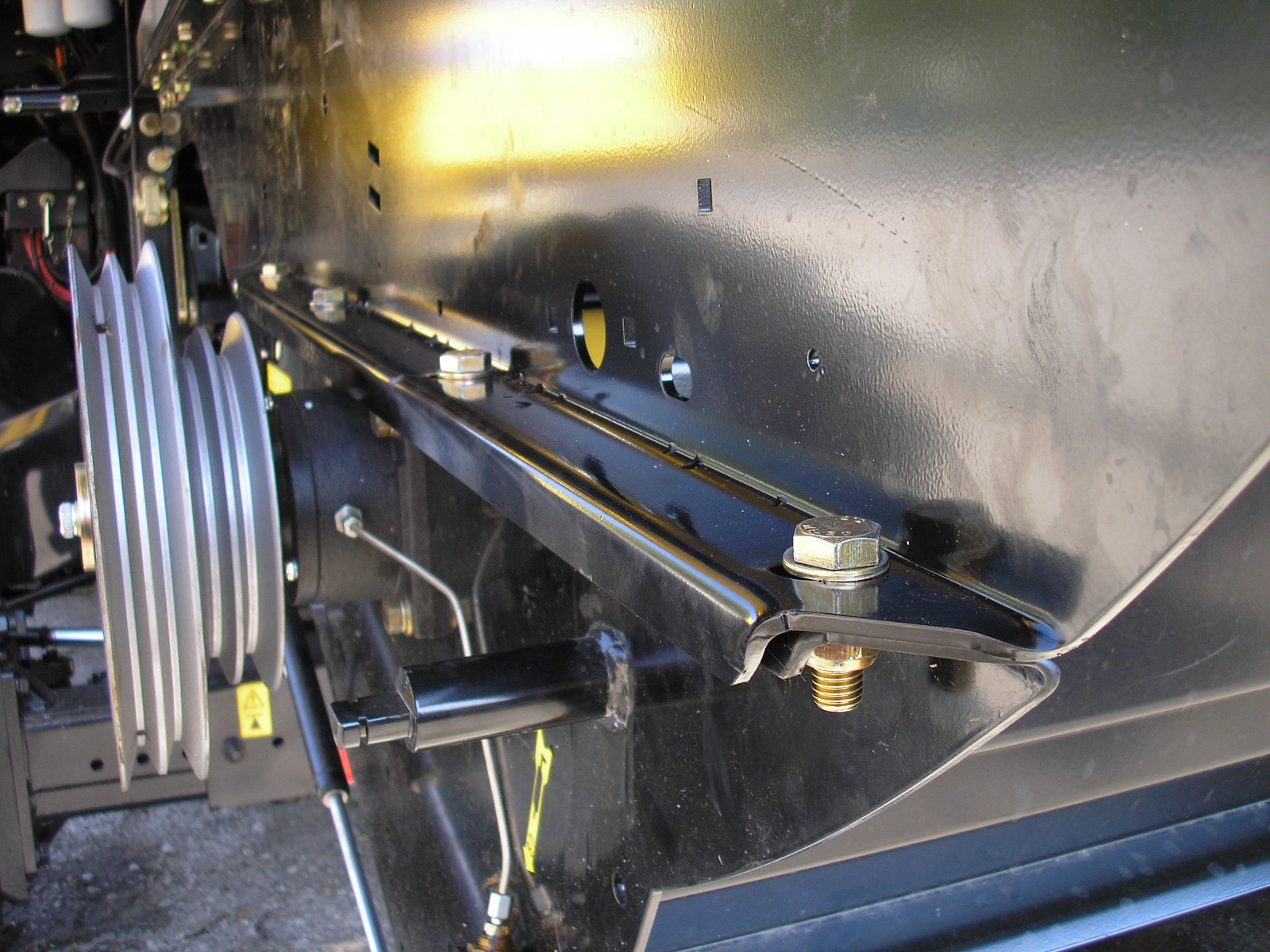

This completely new header with "standard" name CropRanger was first time shown on Agritechnica Hanover 2007 and one year later on Techagro Brno. It was first 12m header with steel frame and very unique integrated support wheels with air suspension. The FLEX module was not missing already in this time. This was the first "touch" of 12m segment.

Unique design of support wheels of the header with air suspension. BISO stand Agritechnica 2007. Look on the drive of auger in the left 1/3 of the header.

The BISO CropRanger VX750 PremiumPlus during the tests in Czech Republic in 2006.

The production and final assembly of ULTRALIGHT models second and third generation was done in Ort factory. On the picture you can see the hybrid frame of 3th generation. The production in this factory started in 1996.

2005 – BISO TERRA ploughs

The first step in the plough segment BISO make with ploughs from Austrian company REGENT. In Slovakia were sold the ploughs in high specification, but the most of unit was sold in Romania.

The New Holland TVT170 with BISO TERRA-5 Vario plough. (Slovakia 2005).

The picture is from Slovakia but the main volumes of this ploughs in BISO colors was sold in Romania.

Model TERRA-5 Vario. (Slovakia 2006).

2005 – BISO SUNPOWER sunflower adapter

Very good product. The professional farmers are looking for such technology during sunflower harvest thanks with a target to minimize the losses. BISO was offering the sunflower kit for CropRanger header, later conversion kit for CornPower adapter (last version is working very good) and in 2005 started production of special adapter for SunFlower with vibration shoes.

Picture from BISO ROMANIA – the SUNPOWER 8-70. The professional farmers are buying for sunflower harvest such a "special tool".

BISO Hurbanovo (Slovakia) – our contracting unit. The BISO SUNPOWER 12-75 is fitted just on CR9090ST, but we are running this unit usually on CX8070SL or CX8080SL with fantastic performance. For harvest with minimum losses you need "speed".

Picture from BISO ROHOVCE (Slovakia) – the SUNPOWER 6-75. It is on CX combine but will work well with much smaller combines.

2005 – BISO SoyaFLEX extension

The SoyaFlex adapter from BISO was in offer in the first phase up to 9m header width. This product is focused on all brands with NO vario headers. In the flex mode the load of knife gearbox, lever and the knife is so high, that actual width limit with one side drive is 7.5m. BISO is able to produce the SoyaFLEX extension for standard headers from John Deere, New Holland, Case-IH, Laverda and Claas. The unique solution is for CLAAS VARIO header up to V750 model.

The mechanical FLEX modul on Laverda header FreeFlow. The knife and double fingers are touching the ground so the wear is high – but result is perfect. On this unit we have standard BISO knife and BISO double fingers.

Laverda M306 with FreeFlow header and BISO SoyaFLEX extension. Slovakia 2017.

Every field of soya is different. On the picture is BISO soya treated by row crop cultivation. The biggest problem is the weed. The BISO SoyaFLEX extension is in comparison with competition very soft (flex module).

Very important is to fit the extension in correct angel on the header. On the picture is CLAAS V750 header. There is no possibility to adjust the angel between combine and header. So the extension must fit perfectly.

BISO is able to produce the SojaFLEX extension only for one vario header – CLAAS VARIO.

2003 – BISO FIELBOSS heavy disc harrow

Original heavy disc from BISO X-type. Available in 5m, 6m and 7m. With disc diameter 72cm it is able to do a hard work. Unique is the front working depth adjustment system (on option). Sold generally in Romania, Slovak and Czech.

Really robust and heavy disc harrow. BISO FIELBOSS 7000 is powerful product which likes 350+ tractor power. After 15 years of fantastic time for "short discs", the customers are starting to look again for such a real disc with all "X" characteristics. Completely produced in BISO SLOVAKIA.

The disc diameter is 720mm (Slovakia 2006).

On this picture you can see the "layout" of BISO FIELDBOSS disc harrows. Front two wheels are the part of working depth adjustment system (as option).

The BISO FIELDBOSS 7000 (Slovakia, 2019). Thanks to the dry weather the request for really heavy disc harrows is coming back. Against 2003 the availability of tractors with 400+ power is no problem jet.

2000 – BISO CropRanger VX vario header

CropRanger means BISO and ... BISO means CropRanger. Production started in 2000 and next year this header got a medal on Agritechnica Hanover. Great success for BISO SCHRATTENECKER. German company in Austrian hands. And with CropRanger BISO introduced a new phenomenon – BISO ProfiTrailer.

First 10 years many people was saying: "CropRanger VX, this is this heavy header". Against simple and standard headers he were really heavy. But ... fantastic product. CropRanger was ok, but some combines where not strong enough at that time. Very popular as used header up till now. Models VX650 and VX750 are perfect. Universal all-rounder. On the picture is CX8080SL with BISO CropRanger VX850 HighLine (Slovakia, 2014). One of the last produced units.

Models like VX900 HL or VX950 HL was a first "touch of frame limit". And BISO have a 20 years of experience with this. BISO stand on Agraria Wels 2009.

BISO CropRanger VX HighLine (HL) usually means – VARIO 70cm, integrated hydraulic sideknives, stainless auger, angle adjustment and plastic reel wrap protection. And every driver will tell you – BISO standard is water and soup canister. On the picture Laverda M306 with BISO CropRanger VX650HL (Czech Republic 2011).

In 2006 was 9m header a "big header". On the picture is NH CR9080SL with BISO CropRanger VX900HL (HighLine). Typical for this headers was stainless auger which have longer life time but generally it is stronger than standard one (Slovakia 2006).

1996 – New BISO factory in Ort im Innkreis

Very nice production place besides highway from Linz to Passau with assembly line for BISO SCHRATTENECKER products, central spare parts storage and with administration center with research and development "in house".

1995 – Schrattenecker overtook BITTER & SOHN (BISO)

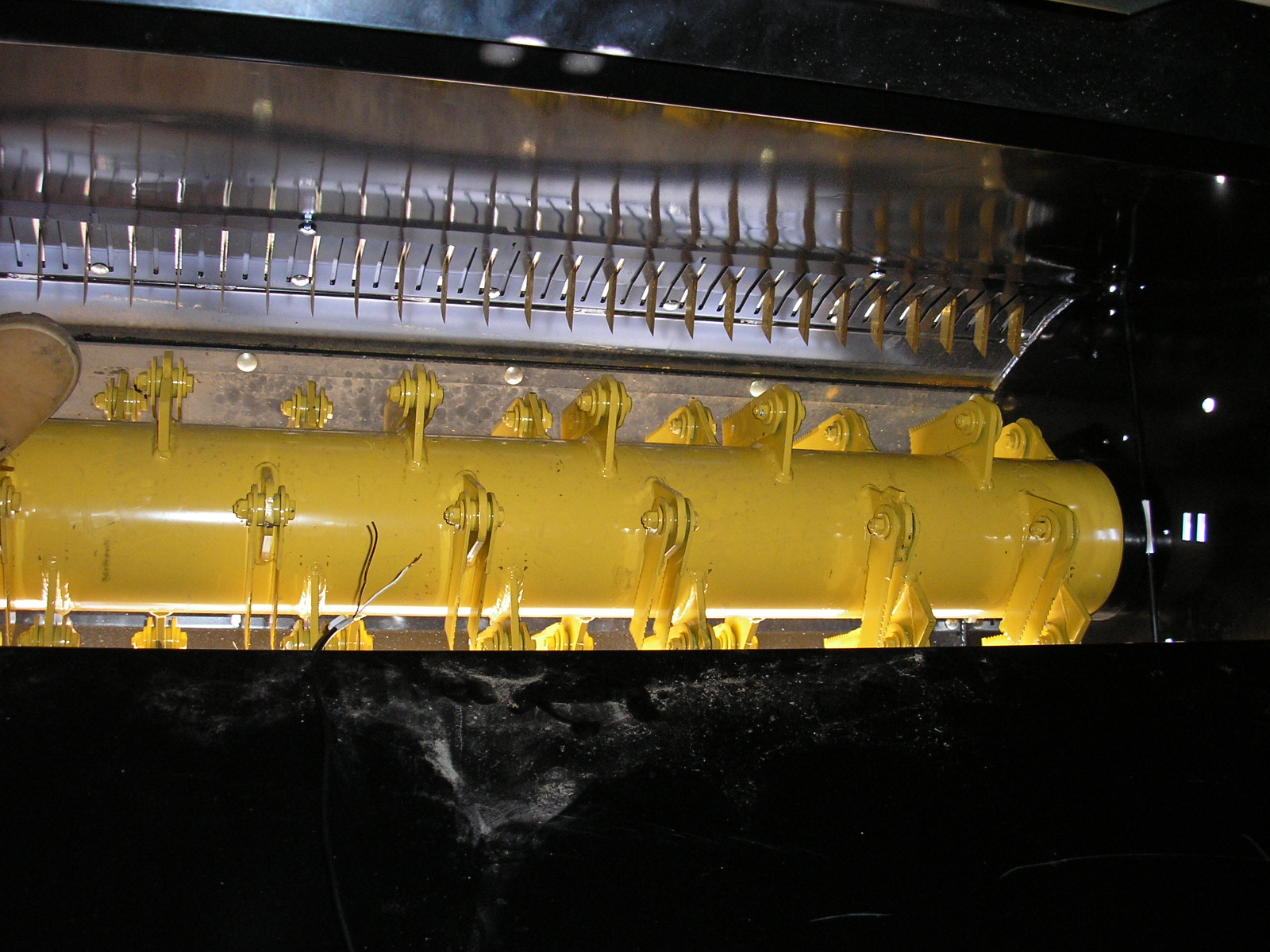

The German company BITTER & SOHN (BISO) produced generally the combine choppers. This was the company with very long history. In 1995 Franz Schrattenecker junior bought this company and moved the production to his home near Scharding in Austria. Next year he built up new factory in Ort im Innkreis.

Combine chopper is a typical product for BISO company. The chopper is a part of BISO logo. On the picture is latest specification of chopper and chaff spreader for NH CX8000 model range.

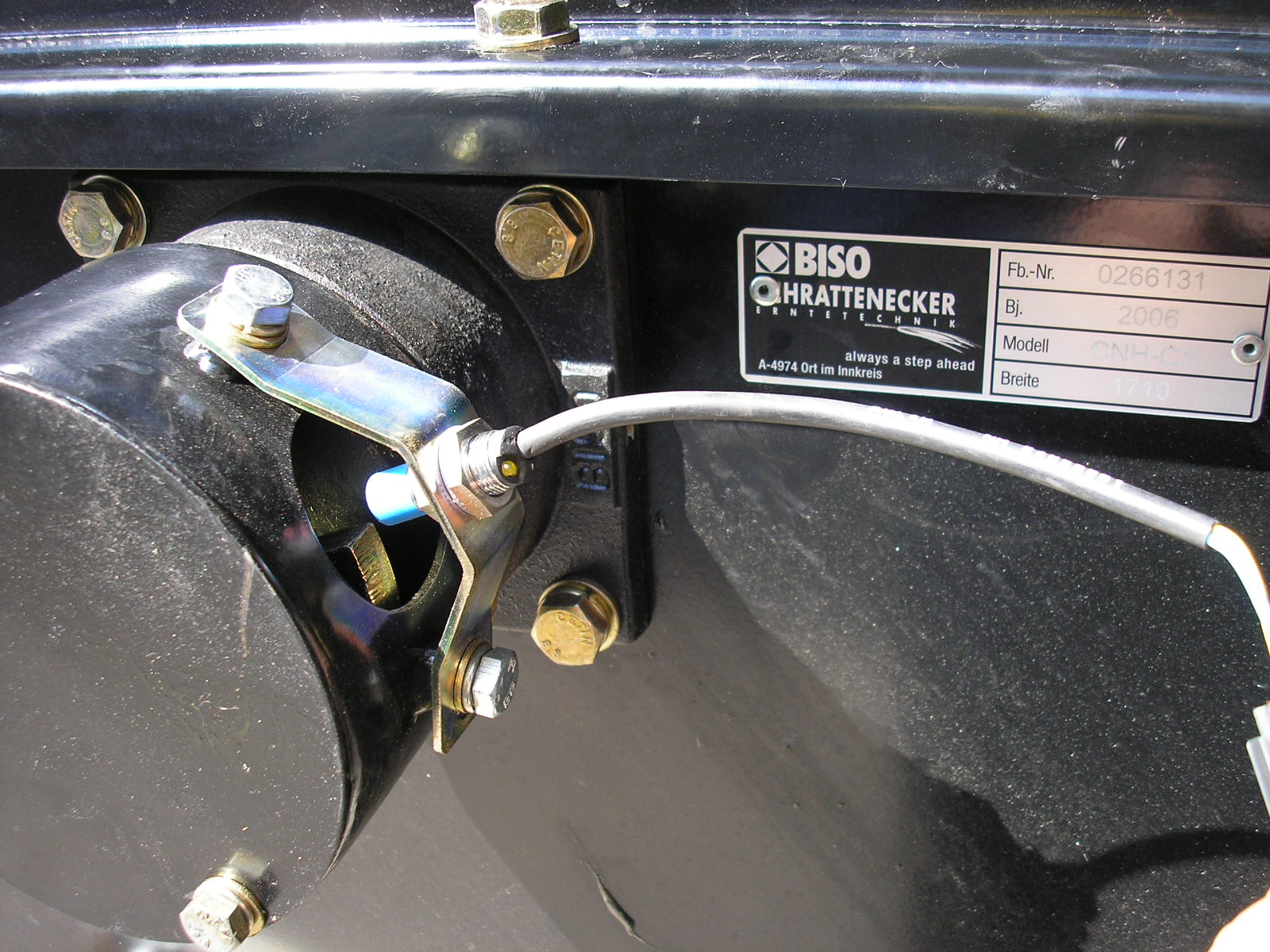

On the picture is the chopper from 2006 for CX8080 combine. In this time was BISO offering the better solution including chaff spreader. Disadvantage was montage of the kit on the combine usually in stress before harvest.

Typical serial plate from BISO SCHRATTENECKER.

1985 – BISO INTEGRAL CX100 rapeseed extension

Key product for BISO SCHRATTENECKER company. On many farms you can find this product up till now. Yellow with typical sticker BISO INTEGRAL CX. This was right product in right time on right place. Rapeseed extension from BISO was produced in top quality in high volumes and the farmers very quickly realized the advantage this technology during rapeseed harvest.

Product for all brands of combines. On the picture you can see the Laverda on Brno Fair in 2010 with BISO INTEGRAL CX. In this time the vario headers already dominated to the markets. But not in all regions and not in all combine power categories.

Perfect demonstration of BISO INTEGRAL CX100 rapeseed extension on Laverda M306LS.

1985 – Schrattenecker – FIAT AGRI Raasdorf dealership

On the base of contract for sale and service of FIAT AGRI machinery the Schrattenecker family opened new branch in Raasdorf (near Wien). In 1990 was built up complete new branch in modern style.

The BISO Eggerding branch. Started with Laverda combines and later with New Holland brand as specialist for combines in Austria.

1983 – Schrattenecker – FIAT AGRI dealership

The family get a contract for sale and service of FIATAGRI tractors (and Laverda combines) including local region in Austria near German border.

1976 – Schrattenecker - new workshop and office in Eggerding

The family built up the workshop for agricultural machinery service and administration building.

1934 – Schrattenecker - family overtook "Schmied in Dobl" in Eggerding

The oldest important note about Schrattenecker family from Eggerding (Austria) is coming from 1934, when they bought the actual place of BISO EGGERDING.

... and what is missing? A lot. The ProfiTrailer, CornCobCollector ....